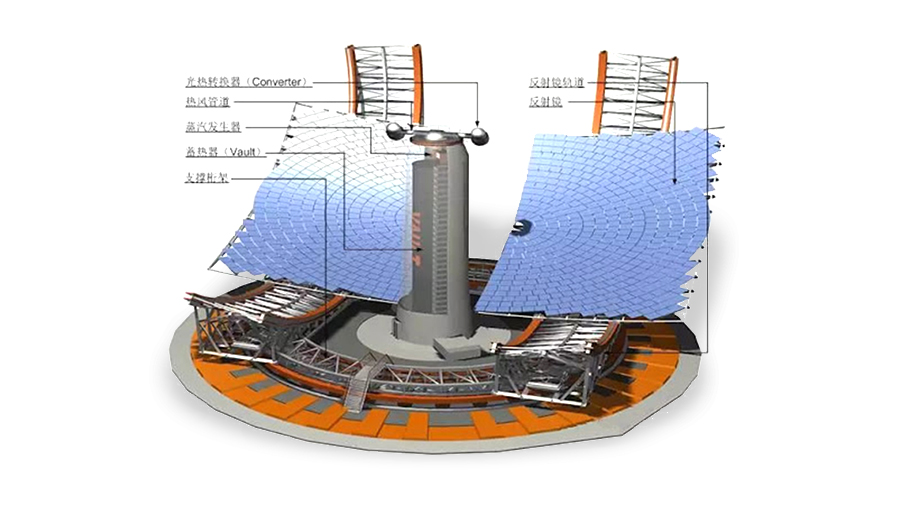

The collector is mainly composed of spherical reflector array, heat absorber, heat storage component, Stirling power generation component, heat exchange component, drive component and control component; its main principle is using the spherical reflection array to focus the parallel sunlight on surface of the heat receiver to heat the HTF (molten salts) flowing inside, the HTF can collect the energy and stored it in the heat storage system, when outputting, the high-temperature HTF is put forward in the heat storage system, which is first sent to the Stirling power generation module for electric energy output, and then sent to the heat exchanger for heat energy output, in order to realize temperature cascade application and cogeneration.

The effective reflect aperture of single collector is 800m2, the concentration ratio is more than 1500, the focal point temperature is 1400 degree, and the output temperature of the heat receiver is about 700 degree. The 700~ 450 degree range is used for the electric energy output of the Stirling power generation in 0.30~0.36 conversion rate, the 450~290 degree range is used for the thermal energy output of the heat exchanger, which can output the thermal energy of 150~250 degree, the overall efficiency of the system is about 0.72 (photothermal efficiency) / 0.22 (photoelectricity).